- Get link

- X

- Other Apps

- Get link

- X

- Other Apps

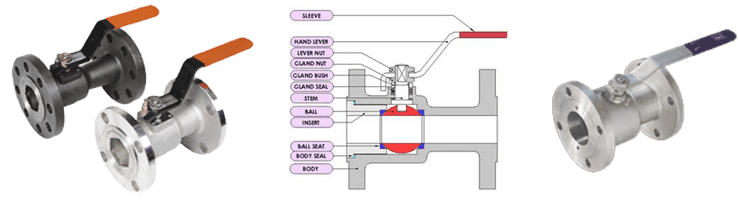

Ball Valve, Characteristics of Ball Valves

Ball valves are mechanical devices that regulate, guide, direct, and modulate the flow of a variety of substances such as gas, pressure, liquids, and so on. D Chel Valves are the leading Ball Valves Manufacturer in India. There are several varieties of ball valves, each with its own design for a specific use, but the fundamental ball valve parts are the same for all of them. Ball valves can be classed based on a variety of characteristics, including:

- Ball valves are readily classified by the number of ports they have. There are two ports on a typical ball valve (1 inlet and 1 outlet). A 3-way port can have one inlet and two outlets, or two inlets and one exit.

- Floating and trunnion-mounted versions are available.

- Unibody, two-piece, or three-piece body assembly.

- Teflon and metal seats are available.

- Full bore, reduced bore, and V-notch bore sizes are available.

- Ball Valves entrance is from the side or from the top.

Types of Ball Valves

Ball Valves have a variety of features, standards, and groups that can help you determine their intended uses and expected performance. Valve designs are one of the simplest methods to filter through the vast array of valves available and discover a good fit for a project or process. D Chel Valves Suppliers and provides solely quality tested Two Way Ball Valves. Ball Valves at D Chel Valves bear several toughness and hardness check before provision them to our purchasers. Our Ball Valves and Their types are manufactured according to International ASTM/ASME, ANSI, API, DIN Standards in India.

Two-Piece Ball Valves

Product Description: Split Body or Two-Piece body design, manufactured in stainless steel and carbon steel, both forged and casting material.

Size range: 1/4-2″.

Three Piece Ball Valves

Product Description: Three-piece body design, manufactured in stainless steel and carbon steel, both forged and casting material.

Size range: 2″-36″.

Fully Welded Ball Valve

Product Description: Manufactured in stainless steel and carbon steel, available in both floating and trunnion ball, fire-safe design.

Size range:1/2-42″.

One Piece Ball Valve

Product Description: One Piece body design, manufactured in stainless steel and carbon steel, both forged and casting material. optional lockable handle, blow-out proof stem.

Size range:1/4-2″.

To know other types of ball valves visit: Ball Valves Manufacturer

Ball Valves Applications

- Ball Valves are used for flow and pressure control and shut off for corrosive fluids, slurries, normal liquid, and gases.

- Ball Valves are used in the oil and natural gas industry, but also find a place in many manufacturing sectors, chemical storage, and even residential uses.

Other Valves Types

- Ball Valve

- Butterfly Valve

- Choke Valve

- Plug Valve

- Check Valve

- Needle Valve

- Gate Valve

- Foot Valve

- Safety Valve

- Orifice Valve

Other Most Selling Valves

- Pinch Valve

- Globe Valve

- Control Valve

- Strainer Valve

- Steam Trap Valve

- Pressure Reducing Valve

- Bellow Sealed Valve

- Air Release Valve

- Pressure Relief Valve

- Trunnion Mounted Ball Valve

Stainless Steel Valves, Carbon Steel, Alloy Steel Valve and many other valves

- Stainless Steel Valves

- Carbon Steel

- Alloy Steel Valve

- Duplex Steel Valve

- Inconel Valves

- Monel Valves

- Titanium Valves

- Nickel Alloy Valves

- Hastelloy Valves

Different types of Flanges are there?

Flange Manufacturer, Suppliers, Stockists in India - Inco Special Alloys

Inco Special Alloys is a leading Flange Manufacturer in India. To meet our clients' needs, we offer a wide range of Stainless Steel Flange in a variety of shapes, sizes, and specifications. Because of their dependability and quality, our Flange are well-known and respected all over the world. Customers are regarded as partners in the supply of our products by us.

What are flanges used for?

Flanges are used to connect pipes, valves, and fittings, as well as specialty items such as strainers and pressure vessels. A "blind flange" can be formed by connecting two cover plates. Bolting is used to connect flanges, and sealing is often completed with gaskets or other methods.

Types of Flanges

We have a trained staff that guarantees the quality of Flange and other items throughout the production and distribution processes, including raw material selection, processing, labelling, packaging, storage, and shipment. Furthermore, we are a well-known supplier of Pipes & Tubes.

Applications & Uses of Flange

Sorf FLanges used Automotive Industry

Flange used in Oil and Gas Industry

Flange used in Pulp & Paper Industry

Flange used in Constructions

Lap Joint FLanges used in Pharmaceuticals Industry

Flange used in Refining Industry

- Get link

- X

- Other Apps

Comments

Post a Comment